Making 3D print product is similar with making pottery, since I have to find certain speed, temperature, layer height, etc.

It can be part of modern craft of machine unlike mass production.

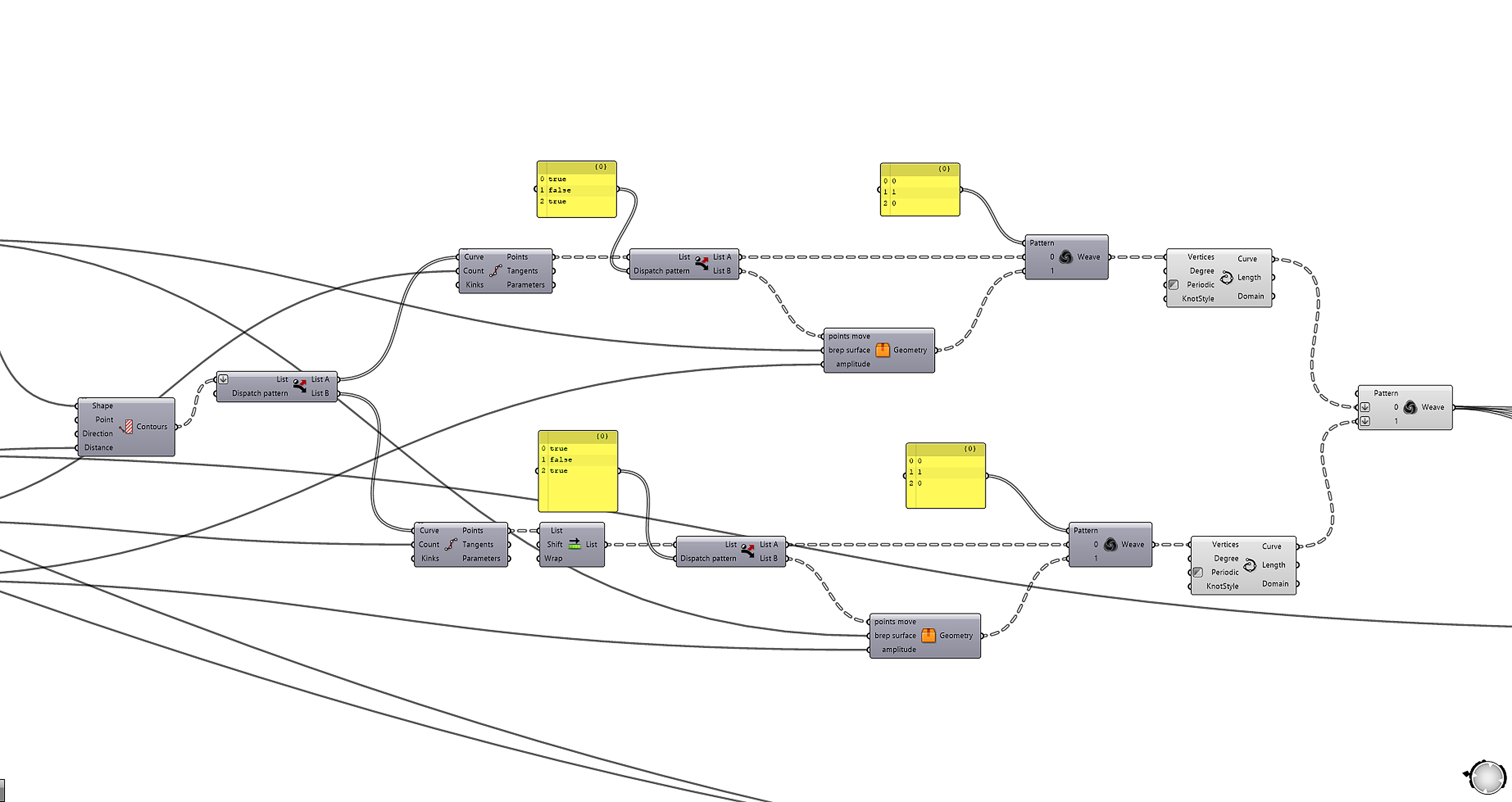

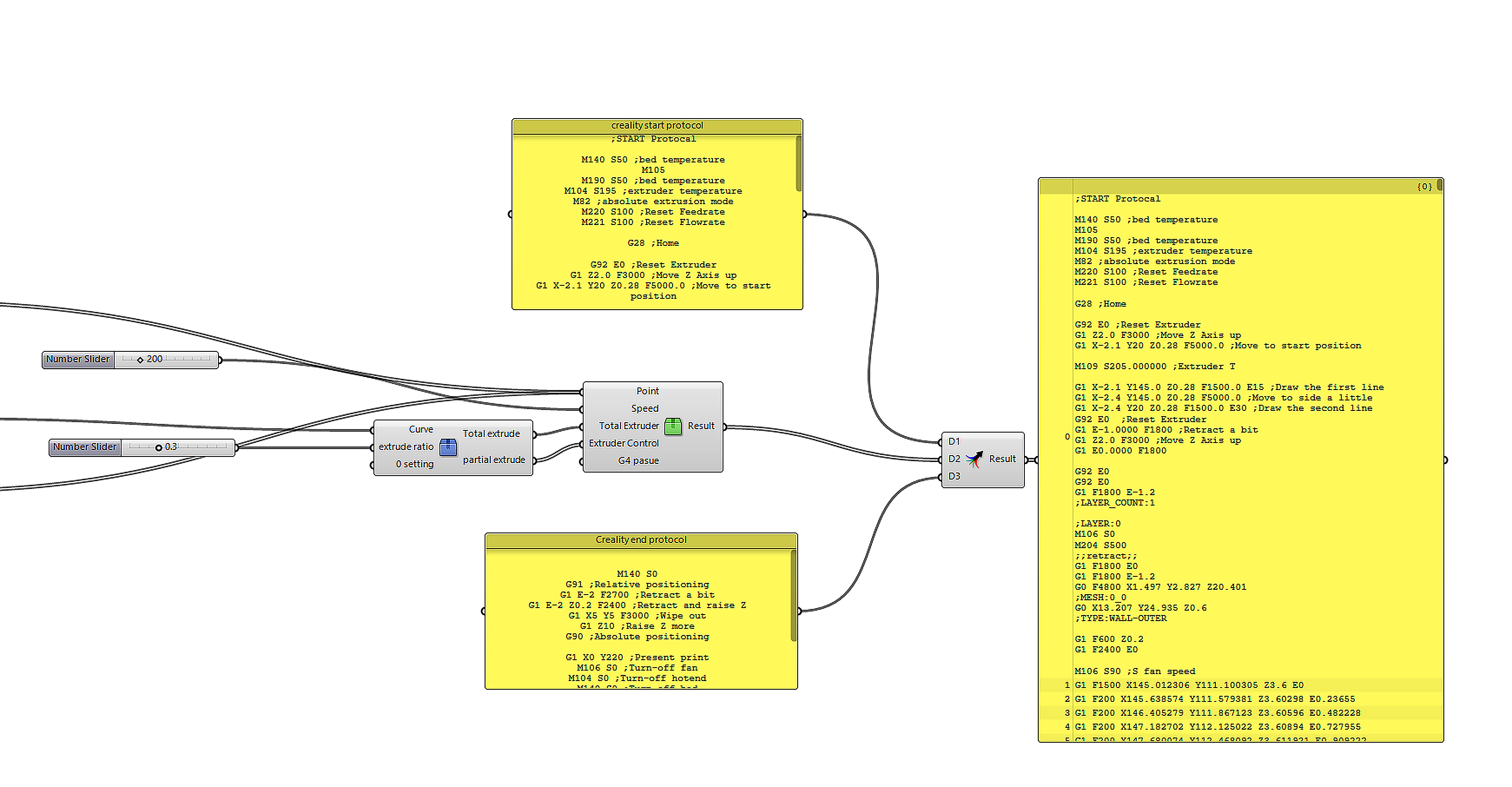

Using Grasshopper to make custom g-code for 3D printing.

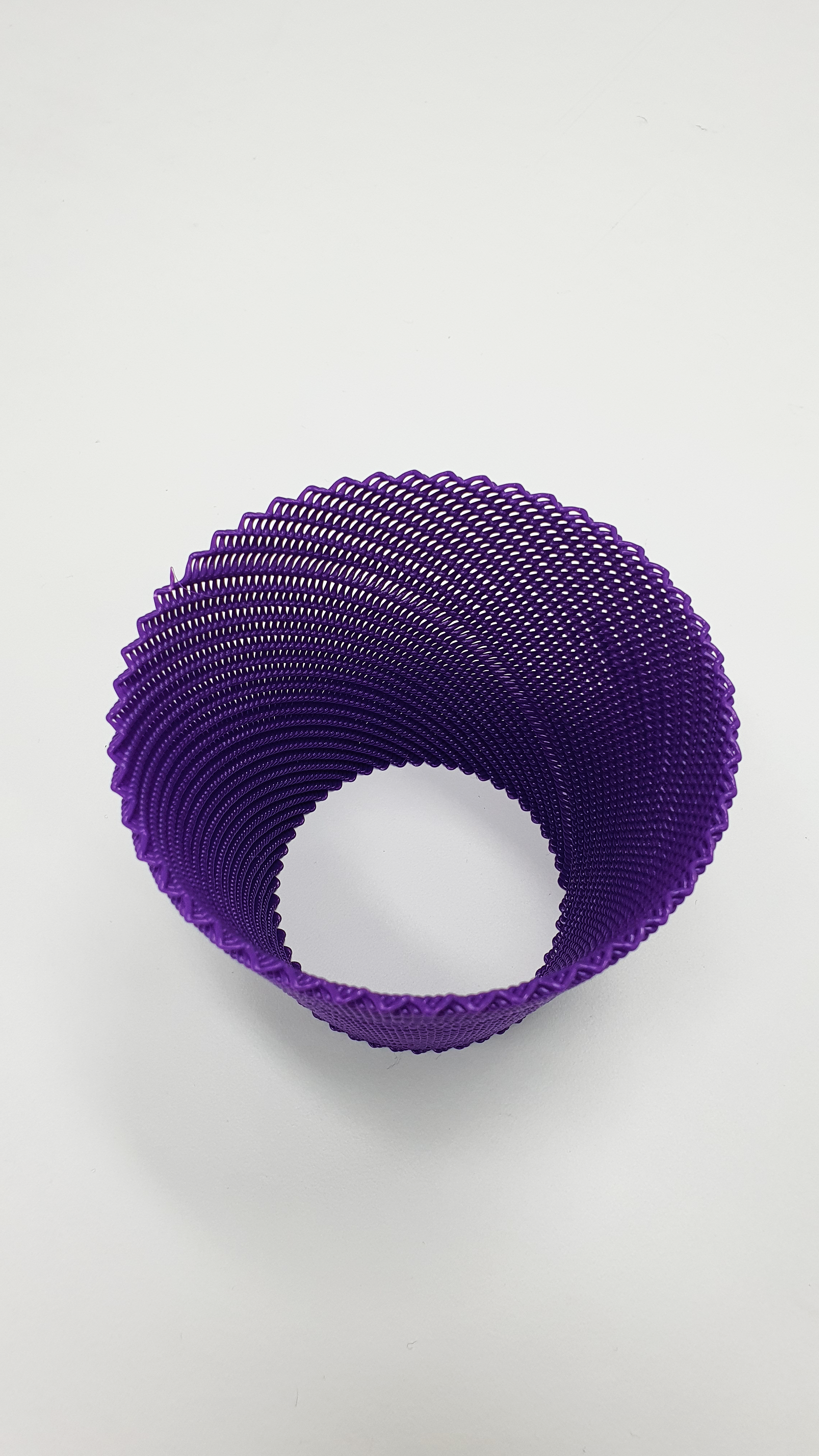

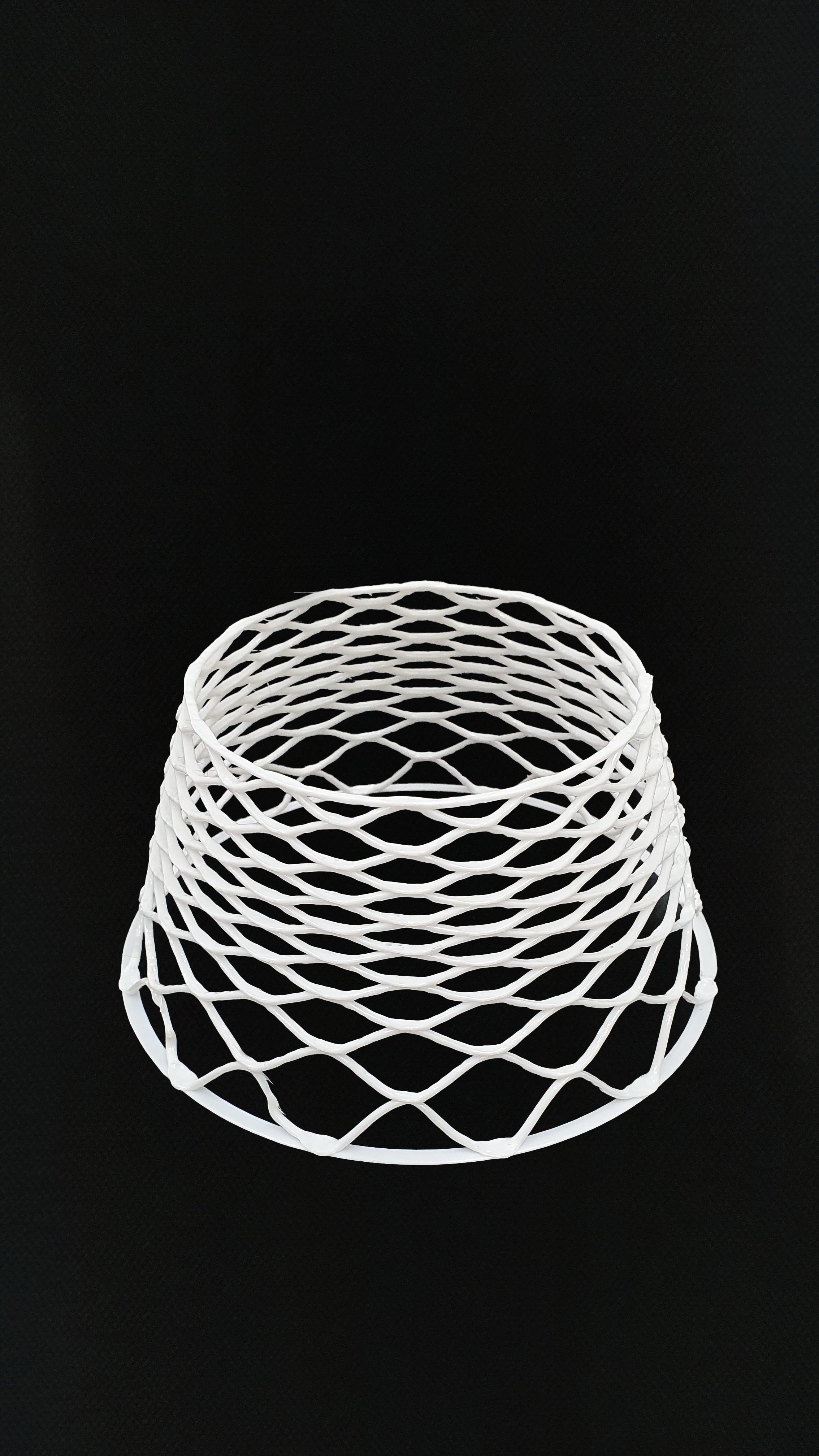

Weaving pattern 3D printing lamp cap.

Vertical printing with single path. It was difficult to find proper speed and temperature to print overhang structure with out any support.

SINGLE PATH 3D PRINT

SING PATH 3D PRINT is an ongoing project aimed at creating unique lampshades using a 3D printer. This project presented two main challenges: designing a unique 3D print path and fine-tuning the appropriate temperature, material amount, and speed for printing.

I believe that creating a custom 3D printing path can be considered a modern craft, as it requires precise control over speed, filament amount, and temperature, similar to how baking fine ceramics involves finding the right temperature, amount of porcelain glaze, and other factors.

To create the custom G-code I desired, I used Grasshopper in Rhino 3D. I researched how to apply my desired pattern shapes to specific forms within Grasshopper. Through extensive testing, I identified the optimal temperature, speed, and material amount to consistently produce high-quality results. It was crucial to use a single 3D printer throughout the process because different printers and materials demand varying speeds, temperatures, and material amounts

YEAR

2024 JAN - CURRENT

ON GOING PROJECT

CATEGORY

3D PRINTING, GRASSHOPPER

MATERIAL

PLA

ROLE

DESIGNER, ENGINEER