The project began with the question: “How much water needs to be filtered after replacing a purifier filter to ensure it’s clean?”

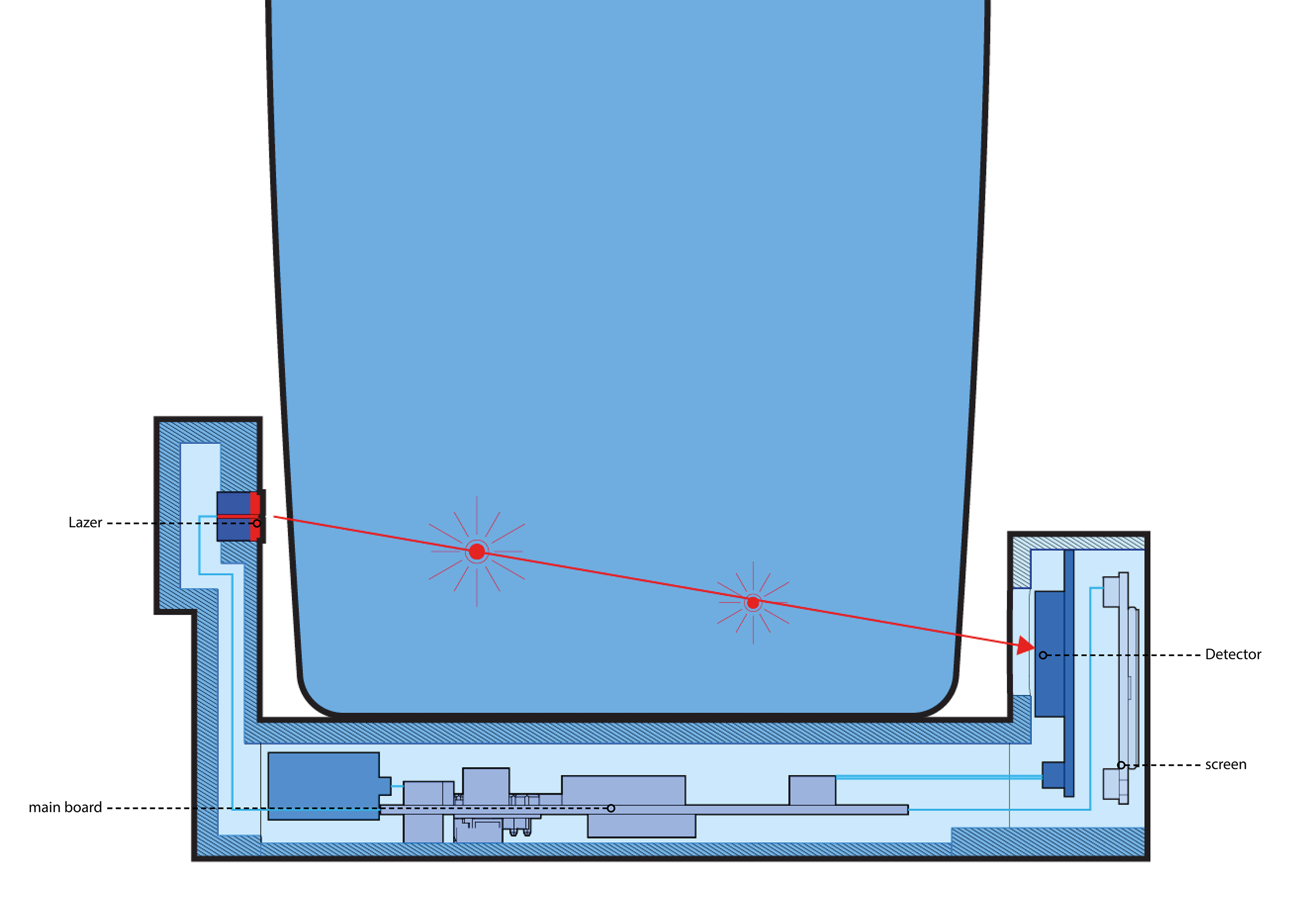

Typically, manuals suggest filtering water 2-3 times before use. We explored how their technology could measure water quality inside the filter during this process. They conducted experiments to determine the number of filtrations required to achieve clean water using their technology.

With optical path amplification technology, sensor detects all foreign substances in water - from turbidity to bacteria and pathogens.

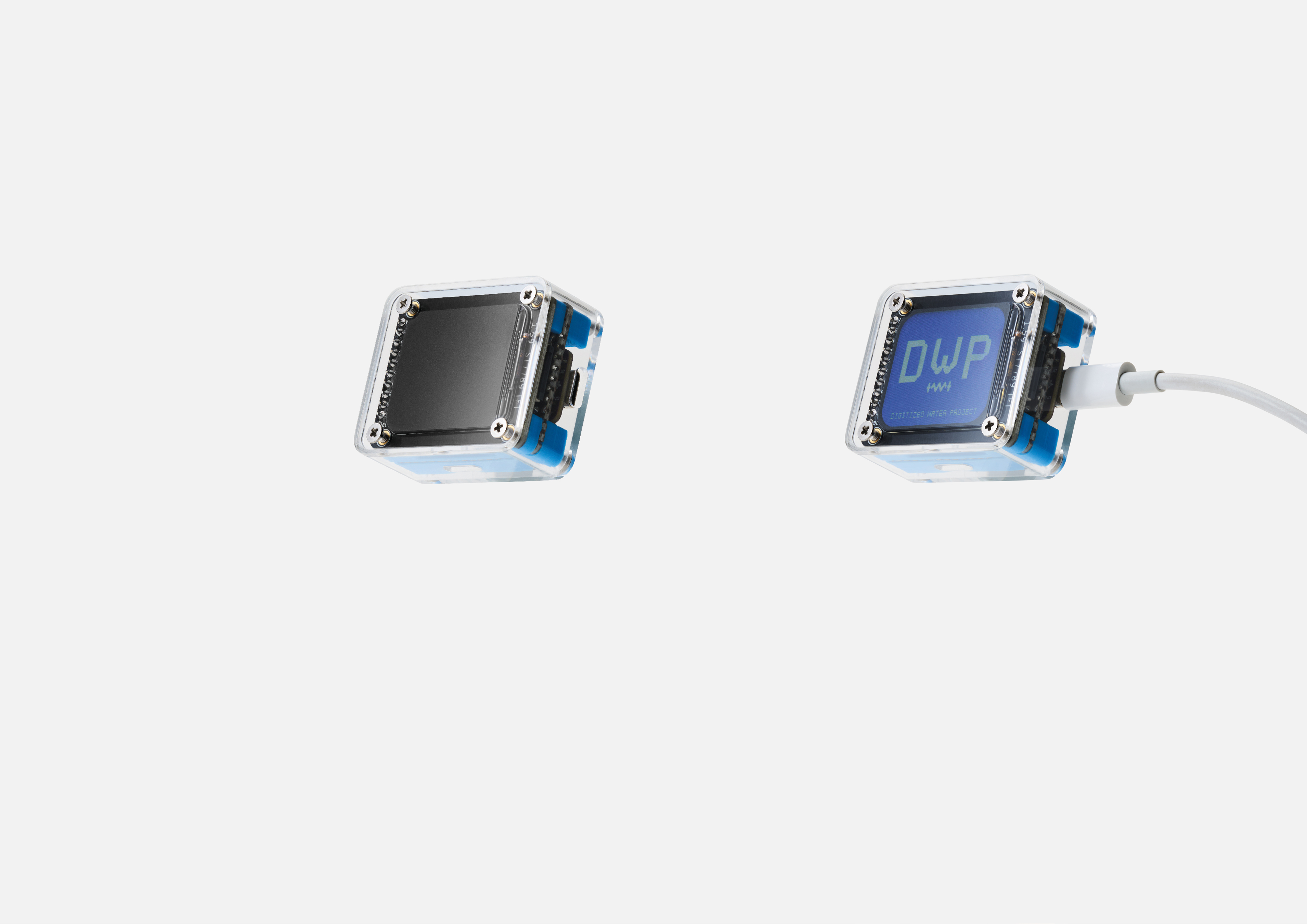

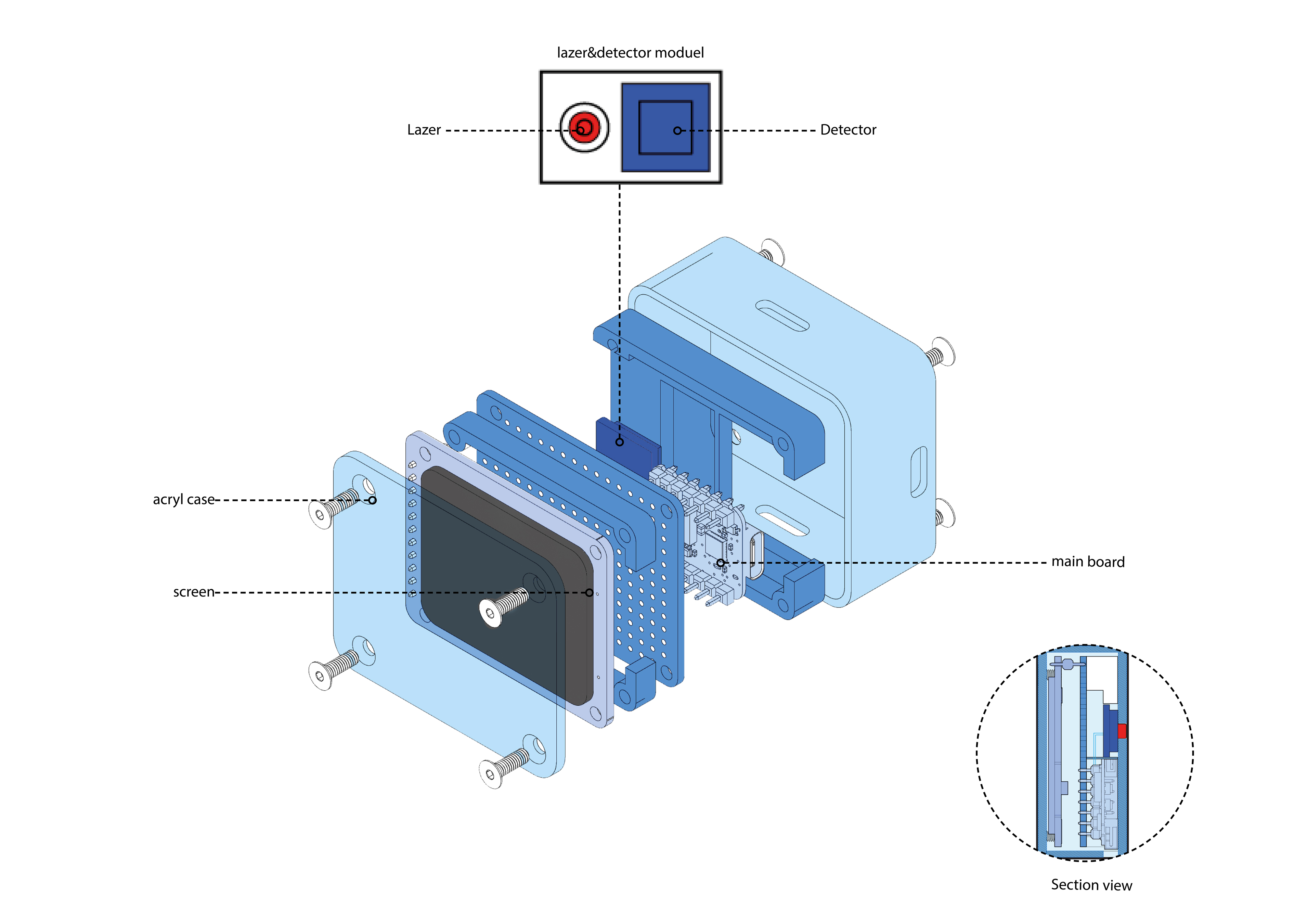

Through the purifier filter prototype, we gained valuable insights and explored ways to trap water in smaller spaces to improve measurement precision. Although bottled water, purifiers, and faucets have similar appearances, their internal structures vary depending on the situation. To accommodate these differences, we designed a simple modular water quality sensor with interchangeable parts, allowing it to be used in various scenarios.

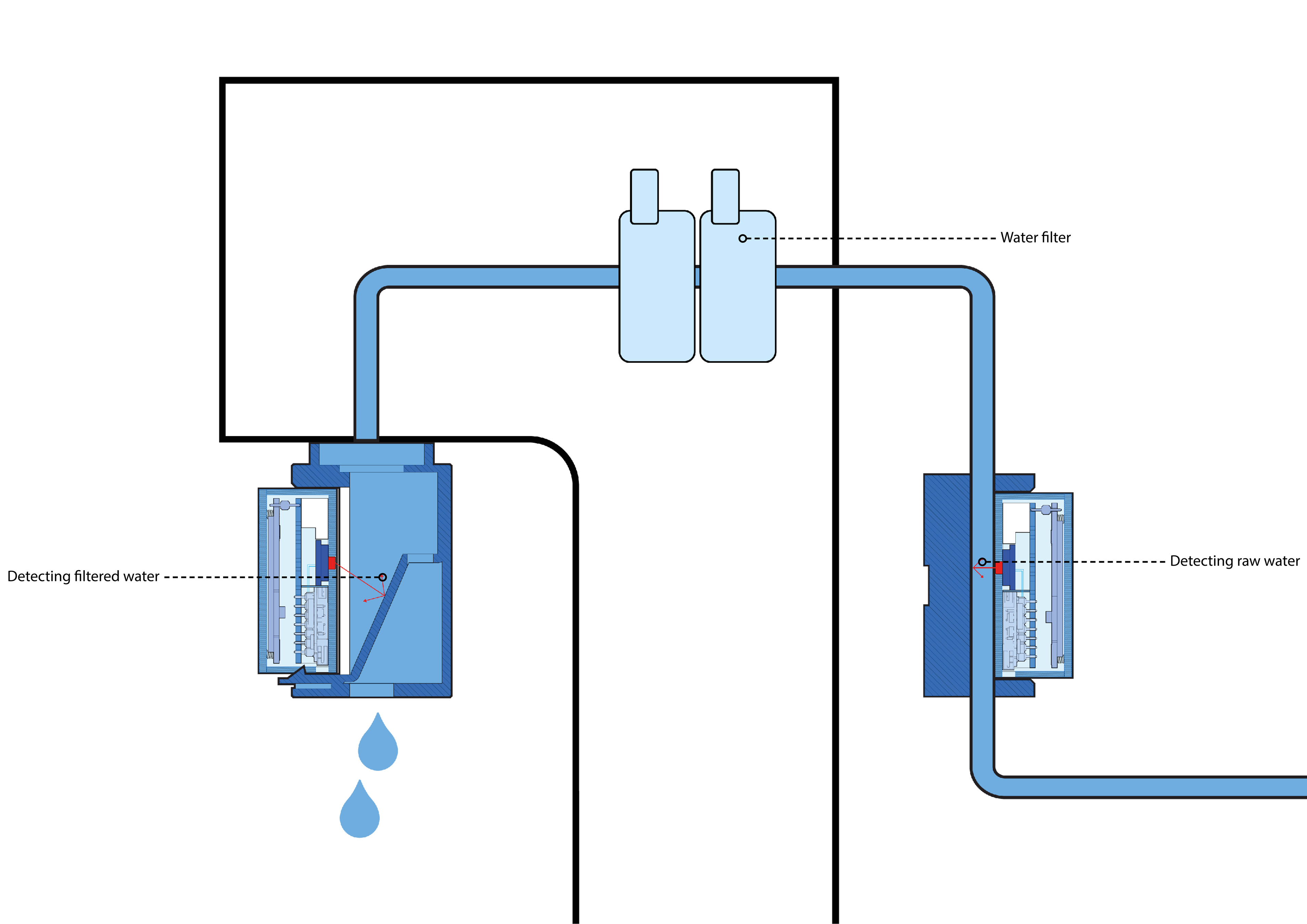

Water purifiers require two types of water quality measurements: one for the raw water entering the purifier and another for the filtered water coming out. By comparing these two measurements, it’s possible to determine how effectively the purifier cleans the water and whether the internal filter is functioning correctly. This precise monitoring can help prevent unnecessary filter replacements by ensuring that the filter is only changed when its performance declines.

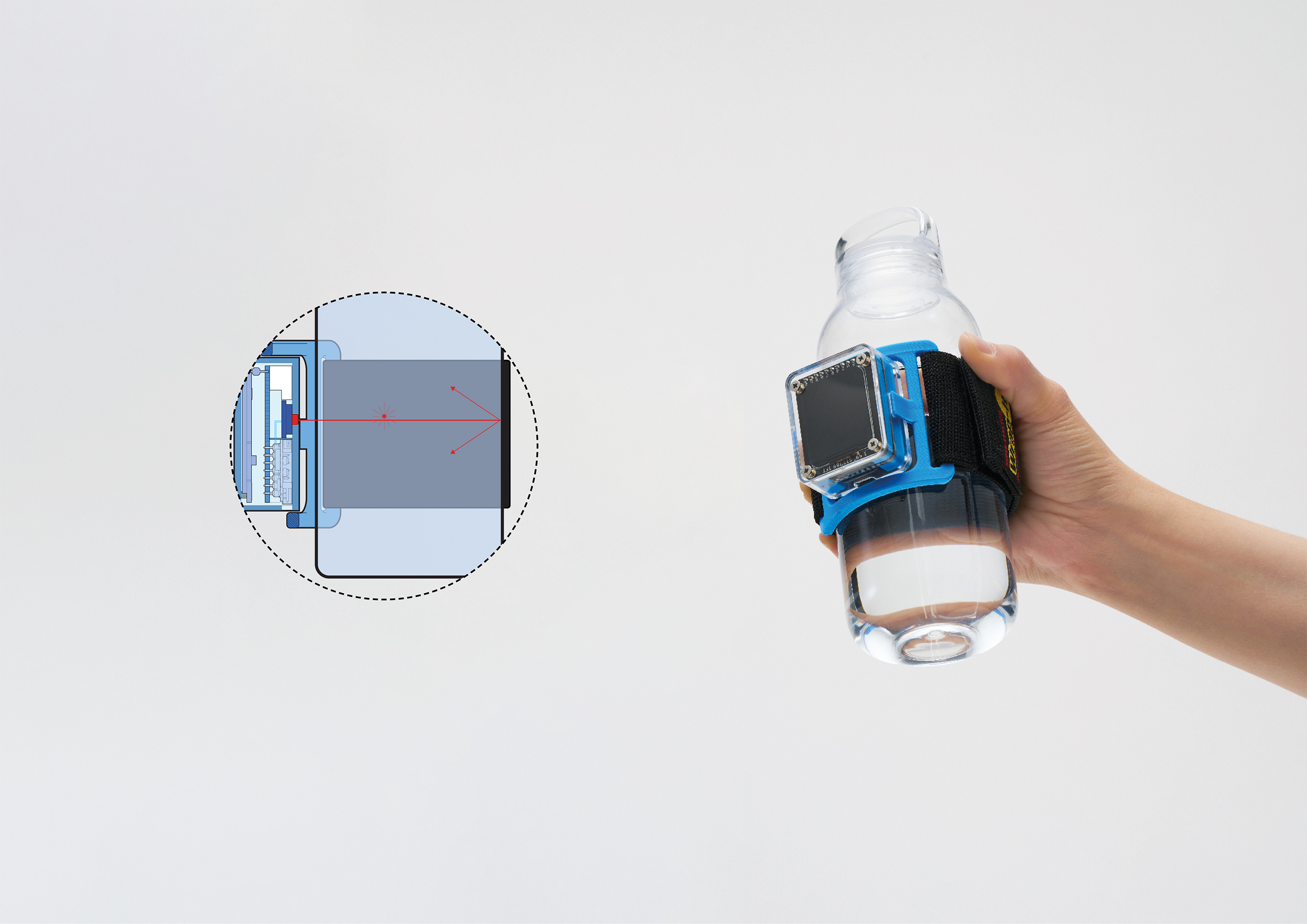

Plastic bottled water can sometimes encounter issues during production. To quickly and easily measure the water quality in these bottles, the DWP module can be attached to the bottle’s opening and inverted. This allows for a fast and simple assessment of the water quality inside the PET bottle.

The faucet module design includes two parts: a connection piece that attaches to the faucet body and a modular unit. This allows for easy replacement if the connection part fails, minimizing damage to the main body. The internal structure directs water to flow from the bottom of the internal chamber, counteracting the high water pressure and ensuring more stable water quality measurements.

The band-type design can be attached to any transparent container, allowing it to measure water quality in not just PET bottles but also various transparent tumblers. This makes it highly versatile and convenient for checking the quality of water in portable containers.

Digitized Water Project

The advanced water quality measurement company “TheWaveTalk” actively utilizes turbidity measurement technology with the goal of providing information that helps society maintain cleaner water. To achieve this, “DWP” (Digitized Water Project) explores how to easily measure and display water quality in various products, such as water filters, purifiers, bottled water, and faucets.

The project initially tested whether water quality could be measured using a filter purifier. Based on these tests, we developed modular sensors and kits suitable for purifiers, bottled water, and faucets. Although each kit’s chamber structure is similar, the detailed design varies depending on how they connect. The structure is engineered to ensure stable water quality measurements across different scenarios. TheWaveTalk’s technology uses lasers to measure turbidity in small chambers with minimal water flow, providing precise water quality readings.

By understanding the water quality of everyday drinking sources such as purifiers, bottled water, and faucets, users can better appreciate the importance of water as a resource and reflect on how they obtain and use water in their daily lives.

YEAR

2024 JAN - 2024 MAY

CLIENT

THEWAVETALK

GROUP PROJECT

CATEGORY

water quality detector

MATERIAL

pla, 3d print, laser sensor module

ROLE

structure DESIGN, prototype making