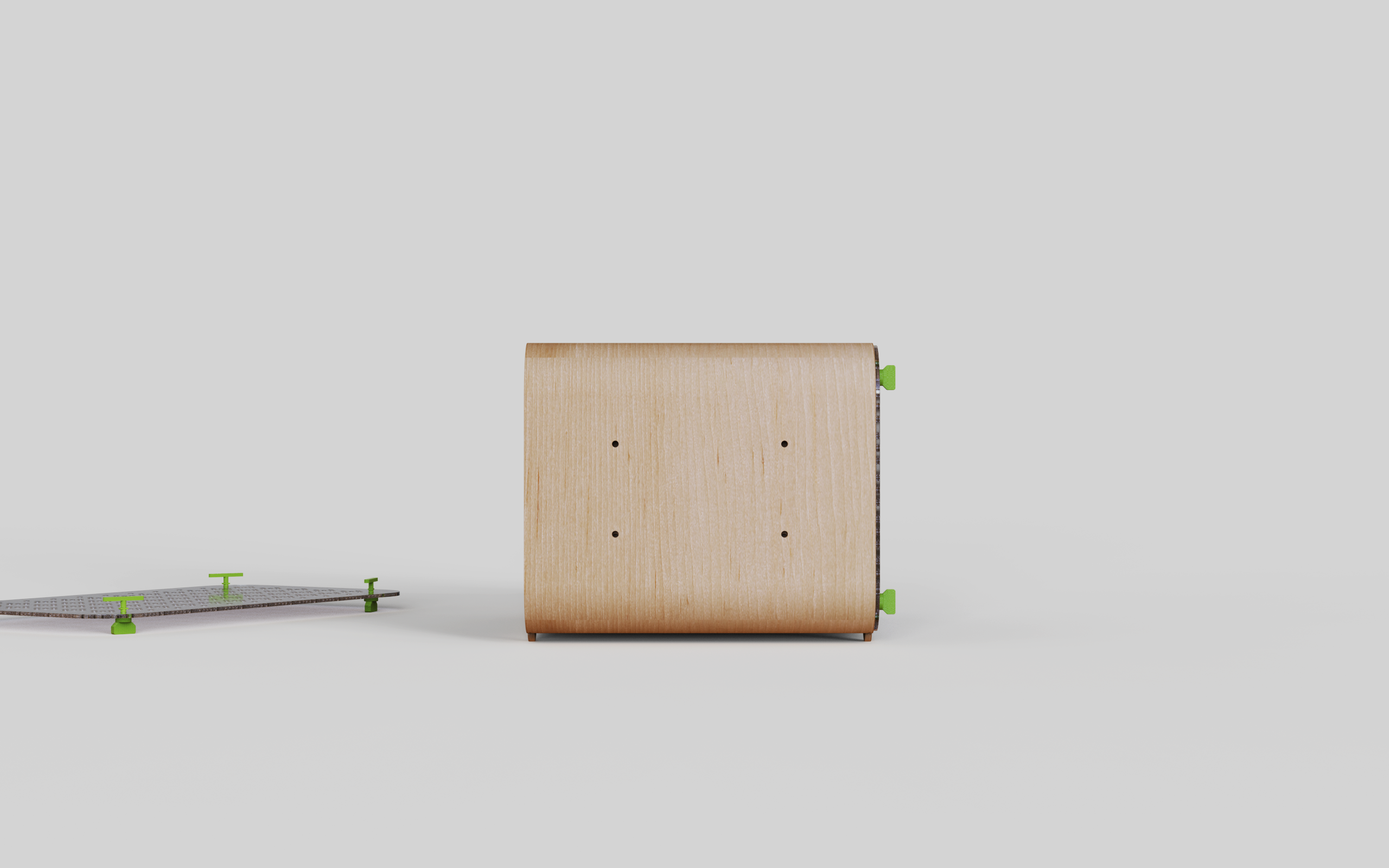

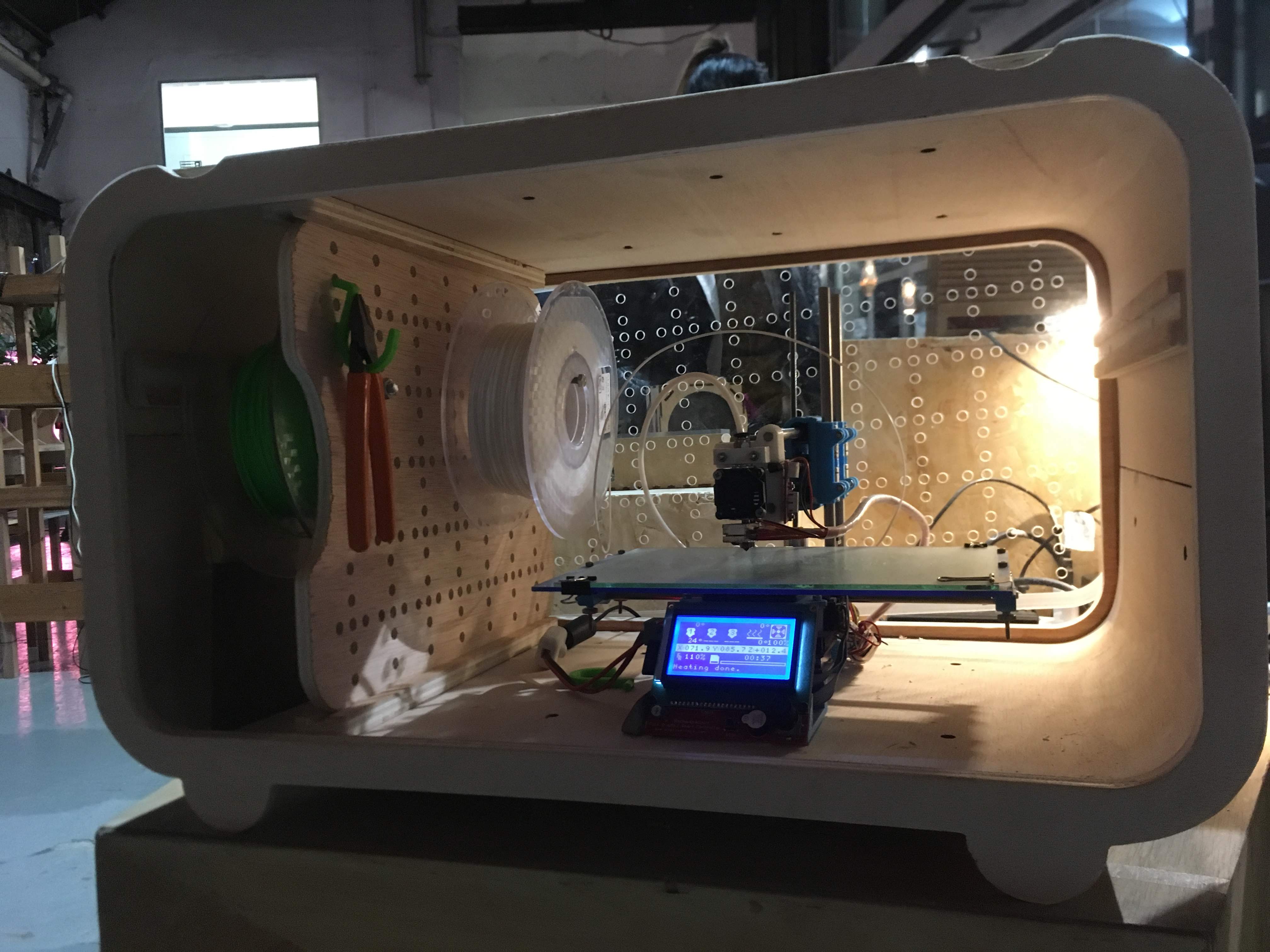

Portable tool box for children’s education which requires various tools by different topics. Stackable box with rounded edge preventing injuries for children.

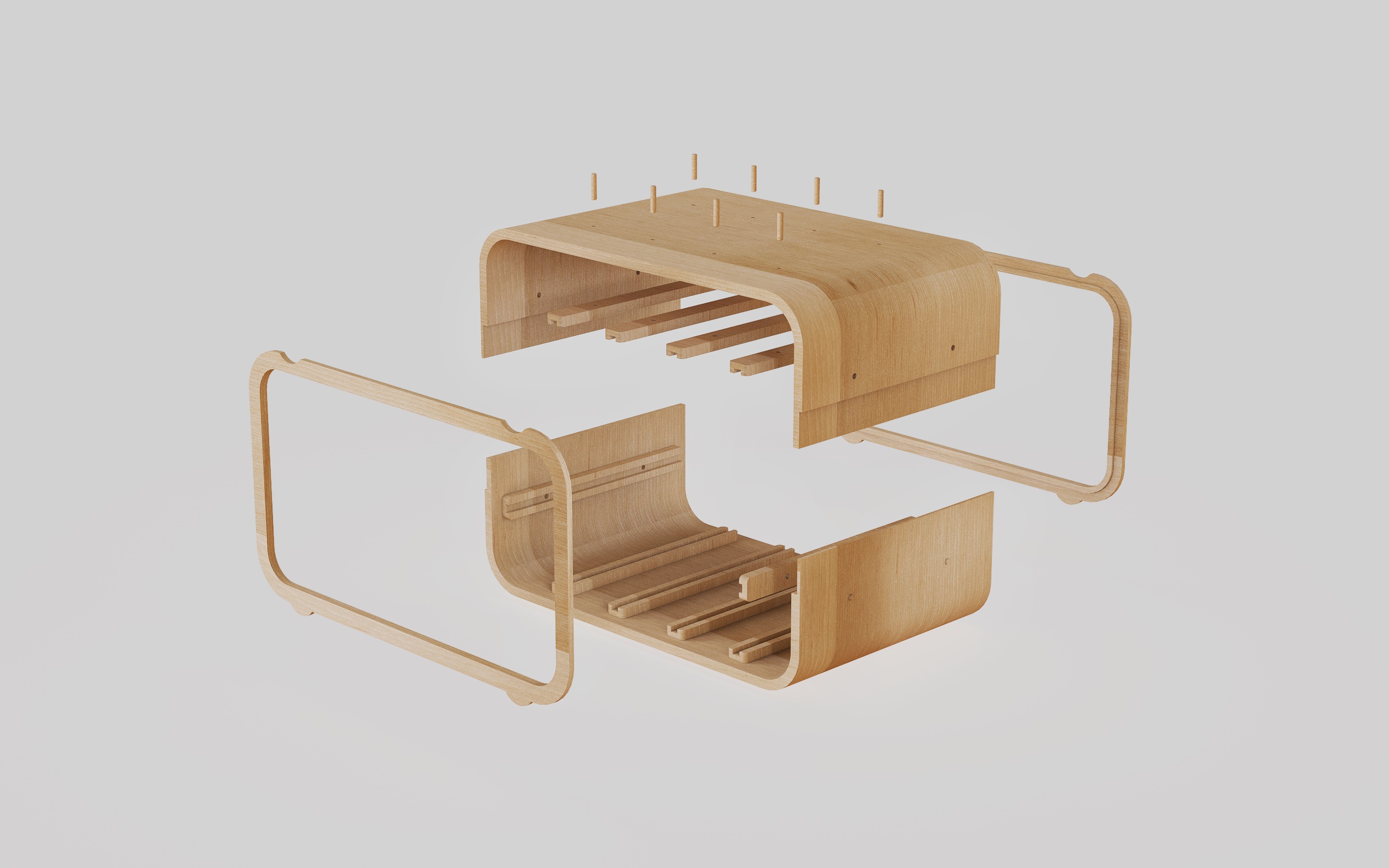

Horizontal and vertical drawers used in different scenarios. Inspired by pegboard, they allow for various tools to be securely fixed in place using wood nails and hooks

Considering mass production, I designed the box structure symmetrically to facilitate large-scale manufacturing using a single mold. The production use vacuum forming and bent plywood.

Reuse the holes used to secure the mold into positions for wall sliders, enhancing both functionality and efficiency.

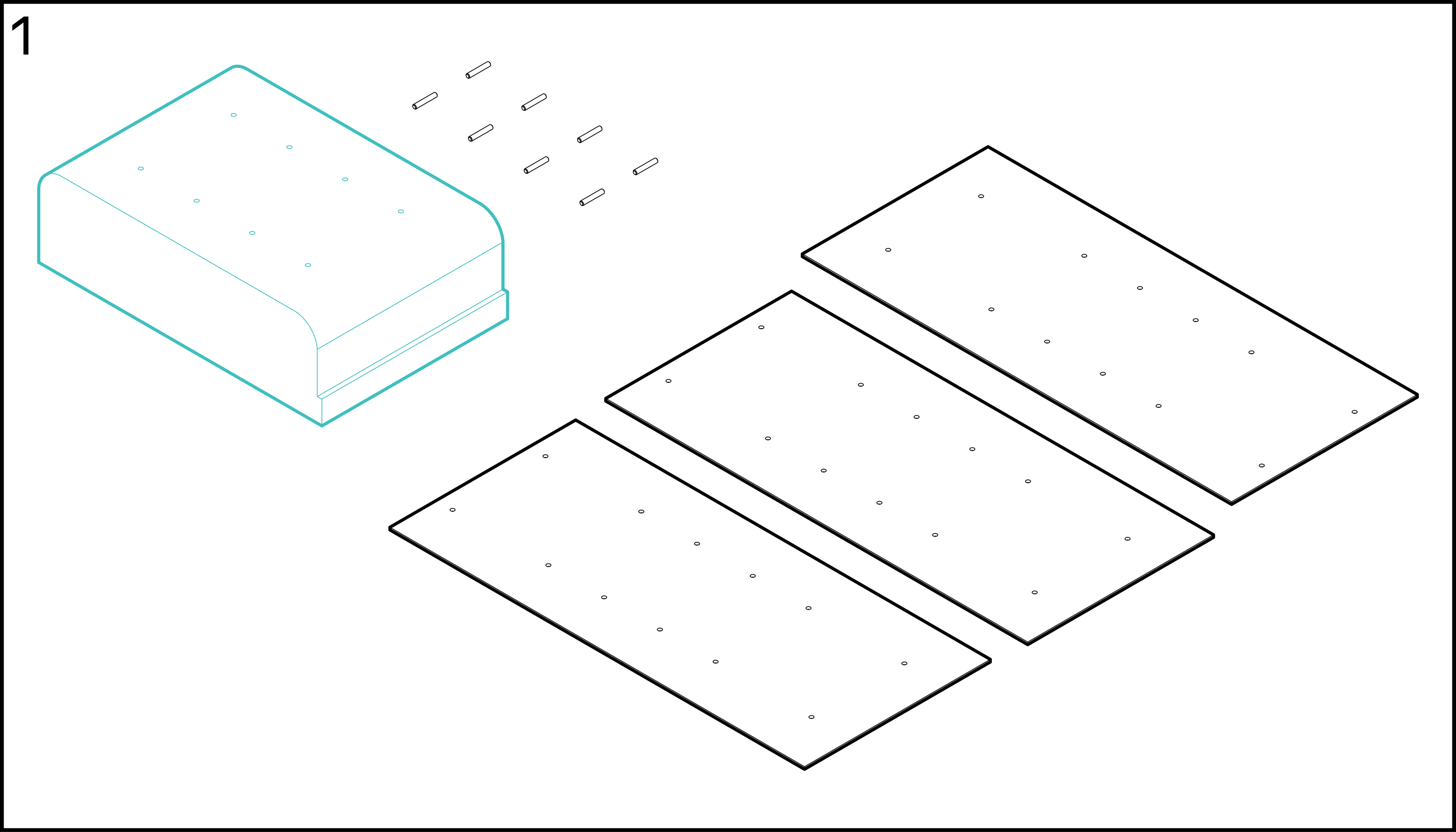

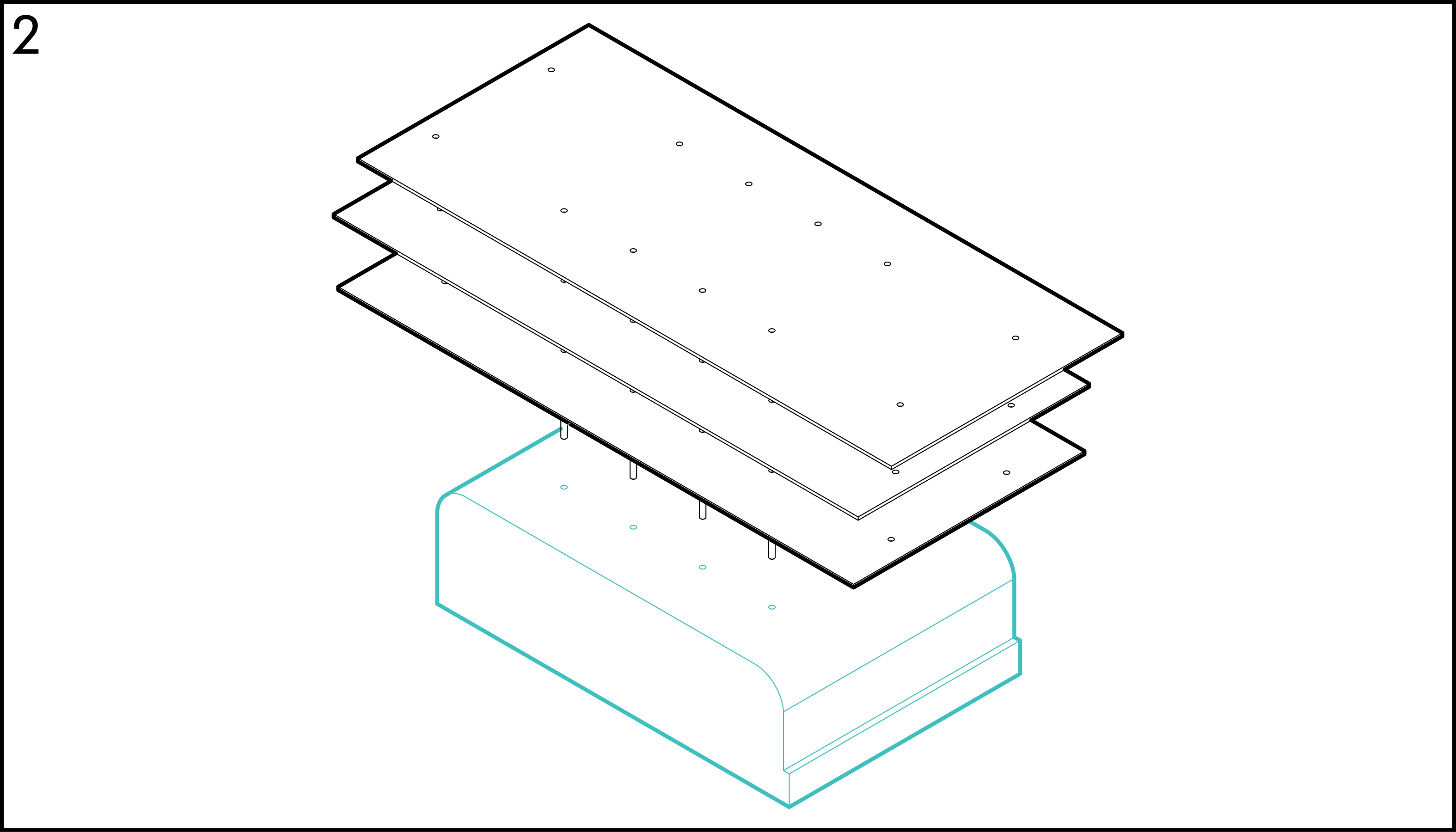

How to make POPUPLAB with vacuum-forming.

1. Prepare mold, 3 bending plywood, wood nails.

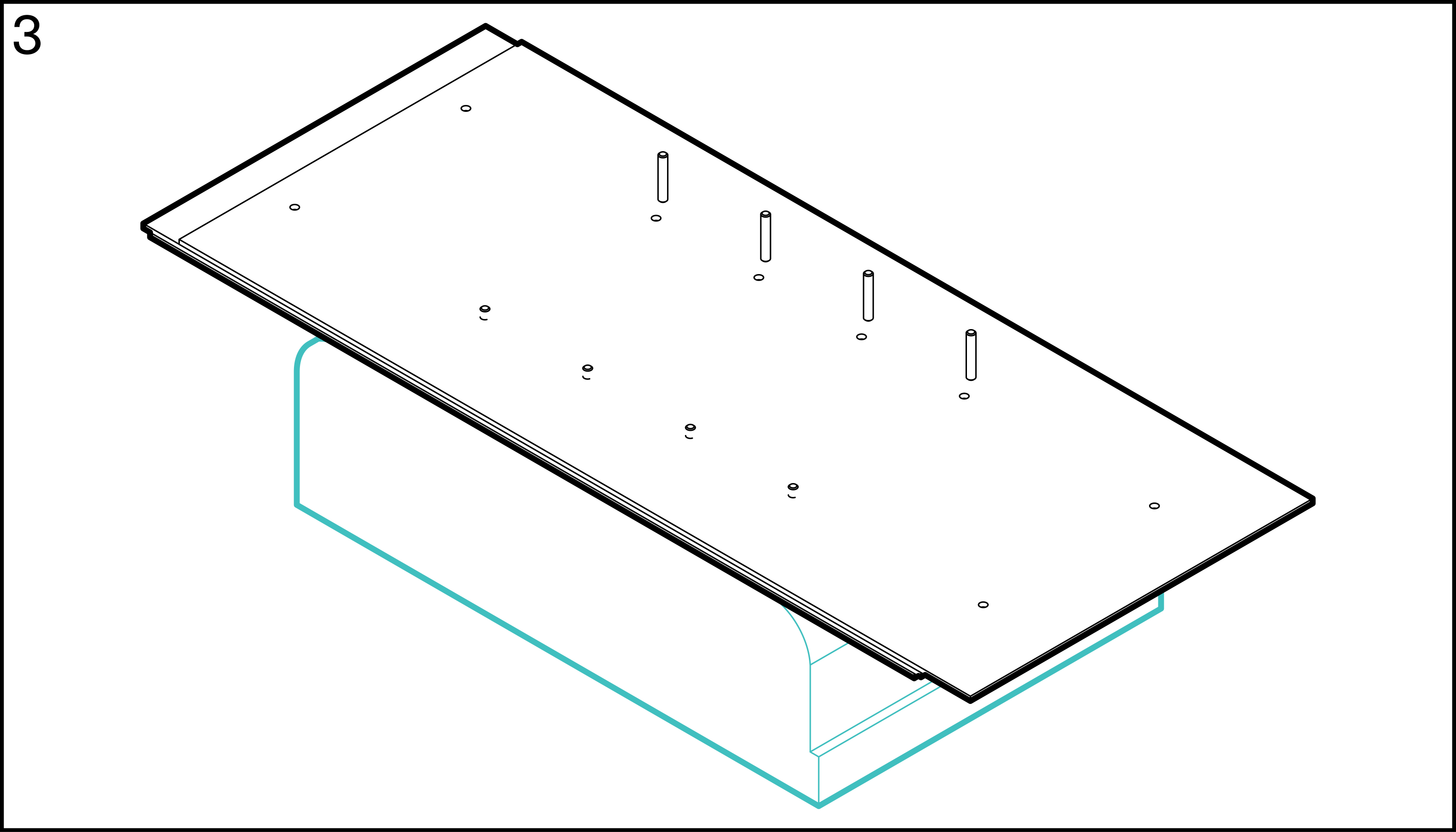

3. Pin wood nails on mold and plywood.

2. Stack 3 different plywood in order. Glue between plywood.

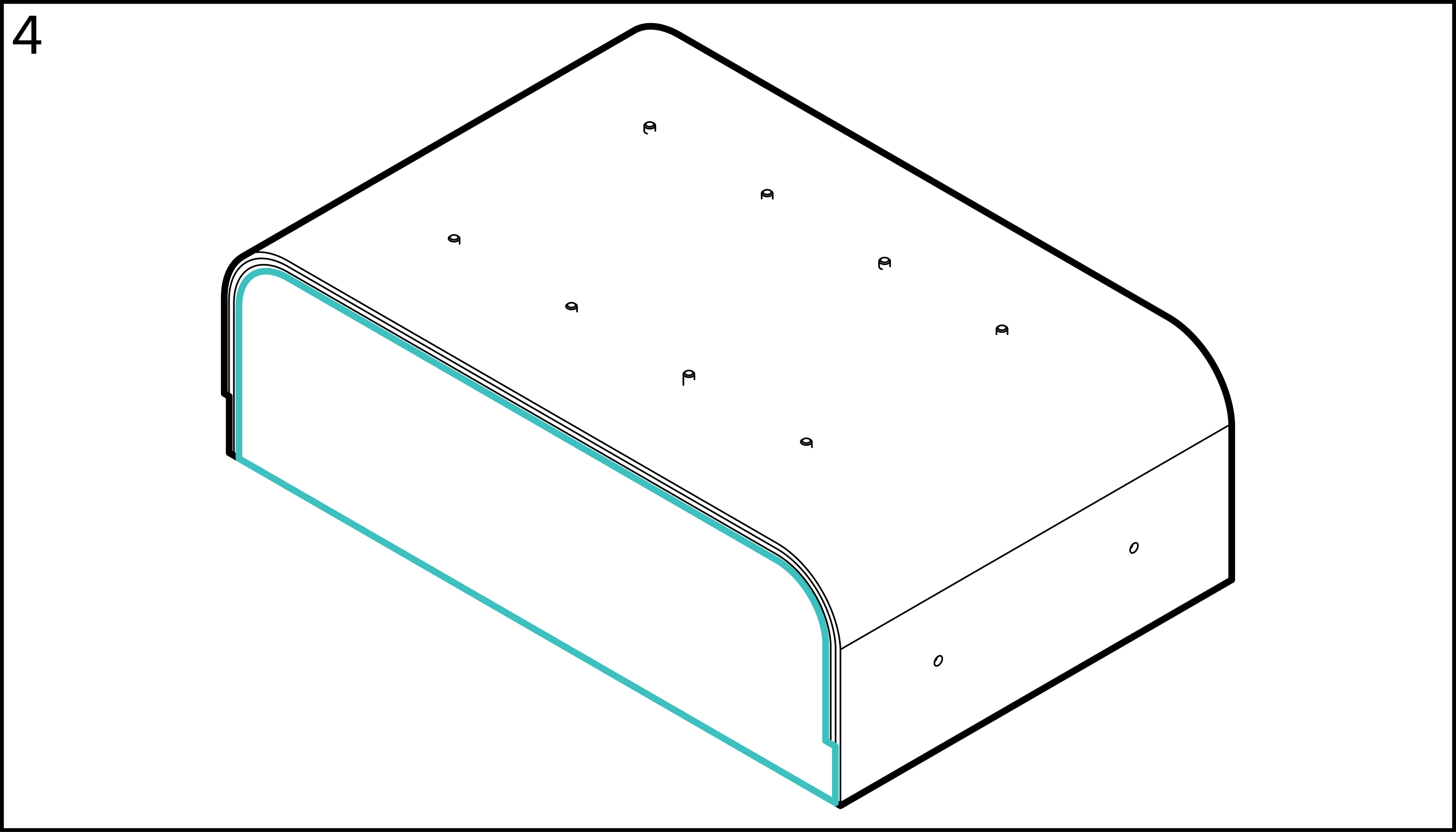

4. Vacuum forming to press plywood on mold.

POPUPLAB

FABLAB BCN needed a portable toolbox for children’s education that could be easily transported by car. The studio mainly used plywood due to its availability and ease of use by cnc. Therefore, we decided to create a versatile toolbox made from lightweight and sturdy plywood, ensuring it was safe for children and usable in various situations.

The design focused on child safety by incorporating rounded corners. To enhance the production efficiency of these rounded corners, I used vacuum forming, allowing to produce the boxes from a single mold. Additionally, I repurposed the pin holes used for securing the vacuum-formed shapes into sliding slits, increasing both production efficiency and versatility.

Inspired by pegboards, the toolbox’s identity centers around the box and slit holes. The hole sizes were matched to standard wood nail sizes, simplifying the sourcing of fastening materials. Overall, POPUPLAB is both functional and easy to produce, making it an ideal solution for versatile educational settings

YEAR

2018 OCT - NOV

FABLAB BCN EDUCATION DEPARTMENT

SOLO PROJECT

CATEGORY

MULTI TOOL BOX

MATERIAL

BENT PLYWOOD,

ROLE

DESIGNER, MAKER